Videojet Labeling Systems

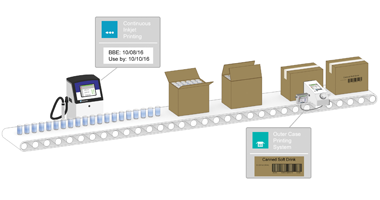

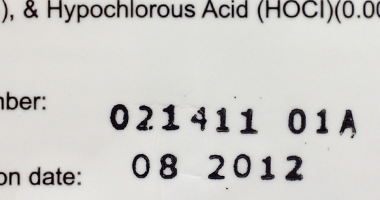

Labeling systems are used to apply preprinted labels to products, individual packages, cartons, cases and pallet loads to identify those unique items. They are also often used to apply labels to products in order to promote the manufacturer’s brand image. The content of these labels can vary from a simple black & white bar code, 1D or 2D code used for identification, to a complex multicolor product label carrying eye-catching brand identity.

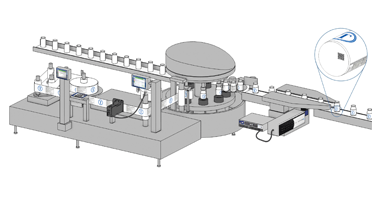

Labeling systems are available in a variety of designs and configurations, each suited to applying labels that meet a specific need. Semi-automatic label printer applicators are set up to manually supply labels to be applied on individual products. Fully automatic labeling machines are integrated into the production process, applying labels to passing products at production line speeds.

These labeling solutions include print-and-apply label printer applicators that produce labels individually that are then applied to packages or shipping loads, and case labelers that record contents of the case. In addition to identifying products, these labeling solutions, to meet the requirements of distributors and retailers, can also place labels that record product ingredients, the temperature at which products have been stored, the brand owner’s brand image, shipping address, etc. They can also print the size type the customer requires, as well as ensuring clear, readable characters and bar codes.

On the production line, labeling solutions are integrated with other line systems and automatically receive the products or packages that are to be labeled. Hand-held manual labeling machines apply a new label on command, which is then applied to the package or product to be identified.

Some labeling solutions and the labeling machines that activate them are a critical element in the need to supply products, packages and pallets with unique identifiers and/or shipping information. These labels are critical to moving products successfully through distribution channels. Pallet loads of products, for example, that arrive at retailers’ docks without complete and accurate labeling may be rejected and returned at the manufacturers’ expense.

Similarly, those labeling systems and label machines that apply brand labels to individual products and packages must be able to apply those labels very precisely, since a wrinkled or off-center label tends to reflect negatively on the product’s brand image. In some cases, these labeling systems also incorporate vision inspection systems that confirm the proper placement and the condition of the applied labels.

Related Articles

Suggested Solutions

Categories

- Automatic Batch Coding Machine

- Automatic MRP Printing Machine

- Bagging Machines

- Bottle Filling Machines

- Carton Labeler

- Extruder Machines

- Flexible Product Packaging

- Food Packaging

- Forming Machines

- Product Marking

- Product Coding

- Production Lines

- Product Labeling

- Tetra Pack Printing

- Tracking & Traceability

- Vacuum Sealers

- Variable Data

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support