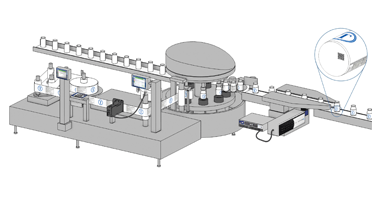

Continuous Inkjet Printing Systems

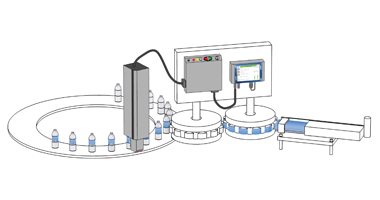

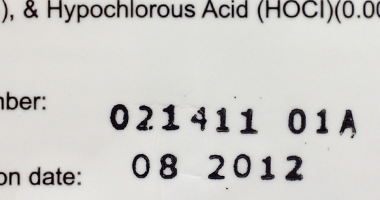

An Inkjet Printing Systems is a machine that places marks on products and packaging by projecting a jet of ink onto the surface of the target. Inkjet coders can print on virtually any substrate material, including paper, plastic, wire, cable, metal, resin, glass, and more. Common symbols printed include expiration dates, lot numbers, serial numbers, barcode, and date codes.

Software within the coder controls the jet to create printed these alphanumeric, 1D and 2D marks. This enables manufacturers to permanently mark their products and packaging to track products through processing, to conform to regulatory requirements and to facilitate quick recall when necessary. In addition, the quick-drying capability of today’s inks limit the risk of smearing or blurred printed codes, ensuring that codes remain readable throughout production and distribution.

The ability of the Inkjet Printing Systems to place these permanent, scannable and human readable codes efficiently and reliably has earned it a place on an extremely wide range of production lines. They are in common use in industries from food and beverage to pharmaceuticals, automotive parts and cosmetics.

Many of today’s sophisticated Inkjet Printing Systems incorporate software that not only enables them to print quickly and cleanly, but also alerts operating personnel when ink or solvent supplies begin to run low. In some cases, the software also enables the manufacturer of the inkjet system to access the unit’s controls to make adjustments and corrections remotely, reducing the risk of production downtime.

Today’s sophisticated Inkjet Printing Systems, such as Videojet’s continuous inkjet (CIJ) printers, also benefit manufacturers by requiring only about 5 minutes of user-performed annual preventive maintenance, either once a year or when the printer reaches 3,000 hours, whichever occurs first. Line personnel can perform this predictable preventive maintenance with no need for a CIJ expert. This helps to eliminate nasty surprises that can cause unscheduled downtime and keeps coders working continuously for maximum productivity.

Related Articles

Suggested Solutions

Categories

- Automatic Batch Coding Machine

- Automatic MRP Printing Machine

- Bagging Machines

- Bottle Filling Machines

- Carton Labeler

- Extruder Machines

- Flexible Product Packaging

- Food Packaging

- Forming Machines

- Product Marking

- Product Coding

- Production Lines

- Product Labeling

- Tetra Pack Printing

- Tracking & Traceability

- Vacuum Sealers

- Variable Data

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support