Semi-Automatic Cartoning Machines:

On semi-automatic cartoning machines, whether vertical or horizontal, the product is inserted in the carton manually by the operator. The absence of an automatic infeed simplifies operation of the machine, but significantly reduces production speed and throughput, and requires the presence of many operators.

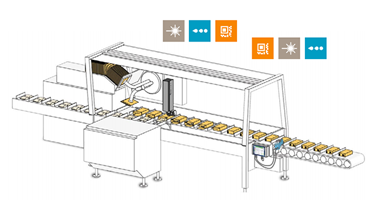

Automatic Cartoning Machines:

There are two types of automatic cartoning machine: continuous mode and intermmittent mode. Continuous cartoning machines are particularly suited to high speed lines, for generally solid and regular-shaped products that do not need special provisions for handling. Continuous operation enables progressive and delicate insertion of the products. Given the high frequency that can be reached (from 60 to over 400 cartons per minute), in may cases it is recommended, or even essential for an automatic feed system to be used. These cartoning machines are often equipped with accessory units, which, for example, fold and automatically insert the illustration leaflets, and apply codes by etching or ink. The continuous or intermittent cartoning machines are designed to pack products in cartons with lateral loading of the product into the carton, and closure of the ends by hot-melt application or flap insertion. The product can be inserted by the operator or via a synchronized mechanical or electronic device, with product collection fro the production line and automatic transfer to the compartments of the machine.

Categories

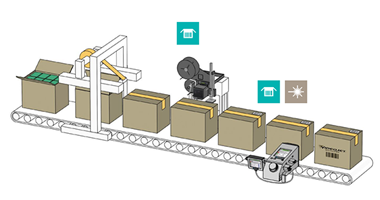

- Automatic Batch Coding Machine

- Automatic MRP Printing Machine

- Bagging Machines

- Bottle Filling Machines

- Carton Labeler

- Extruder Machines

- Flexible Product Packaging

- Food Packaging

- Forming Machines

- Product Marking

- Product Coding

- Production Lines

- Product Labeling

- Tetra Pack Printing

- Tracking & Traceability

- Vacuum Sealers

- Variable Data

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support