Also see:

Videojet 1880 Industrial Inkjet Printer

Continuous Inkjet Printers ![]()

The Continuous Inkjet printer manufactured for Industry 4.0 productivity pioneers

The Videojet 1880 CIJ printer builds upon millions of hours of real-world printer data to deliver a digitally-enabled solution that helps to ensure your production line operates without interruption.

With an industry-first ink build-up sensor and Videojet MAXIMiZE™ built-in diagnostics suite, the 1880 is designed to reduce your main causes of unplanned downtime.

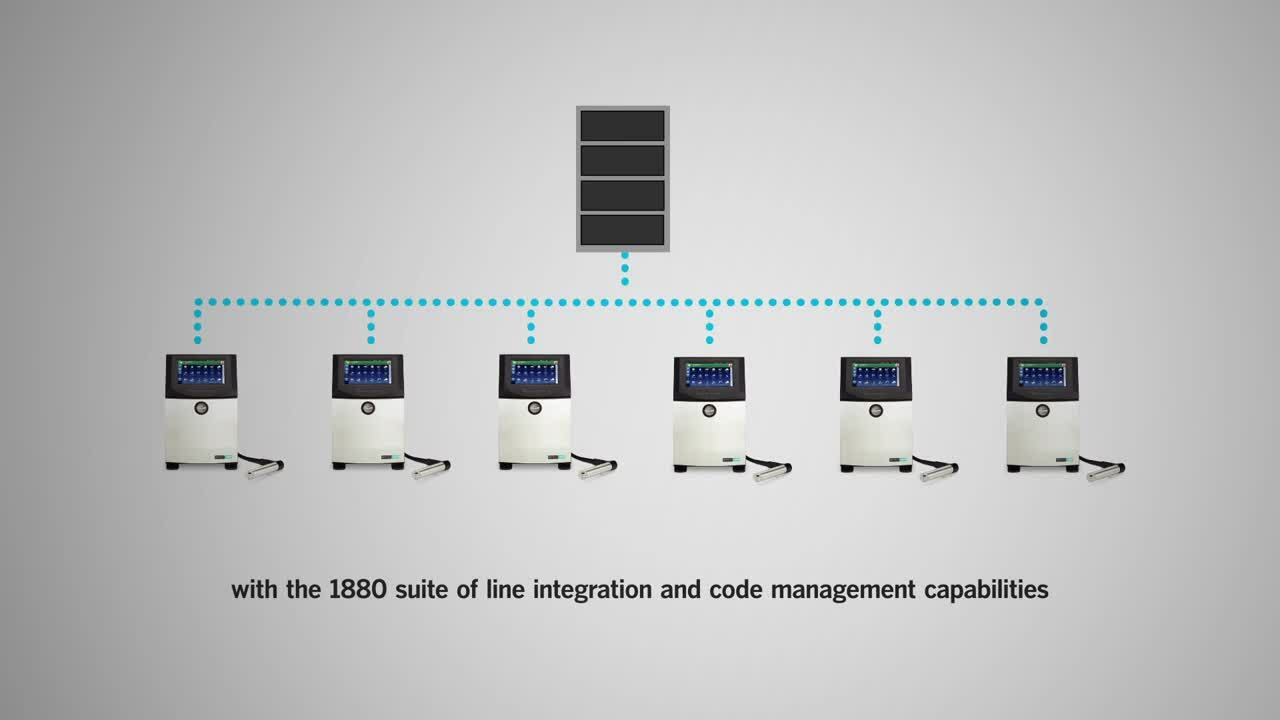

Line integration and code management capabilities reduce potential for human error and help to ensure you get the right code at the right quality, every time, while advanced features minimize operator interaction so you can focus on your production.

Contact us for New Equipment Sales: 7506345599

Videojet 1880 Industrial Inkjet Printer

Specs

| Value | |

| Printheads | 1 |

| Inks | Dye Based |

| Maximum Lines of Print | 5 |

| Maximum Line Speed (1) | 334 m/min (1,097 ft/min) |

| Environmental Protection | IP55, IP66 |

| Umbilical Length | 3m (9.8 ft) optional 6m (19.6 ft) |

| Message Storage Capability | More than 250 |

| Smart Cartridge™ | Included |

| Plug and Play Printhead Modules | Included |

| USB | Included |

| Communications | Ethernet LAN and RS-232 Serial (requires RS232 connector kit) |

| Positive Air / CleanFlow™ | # |

| Expanded I/O Ports and Control | # |

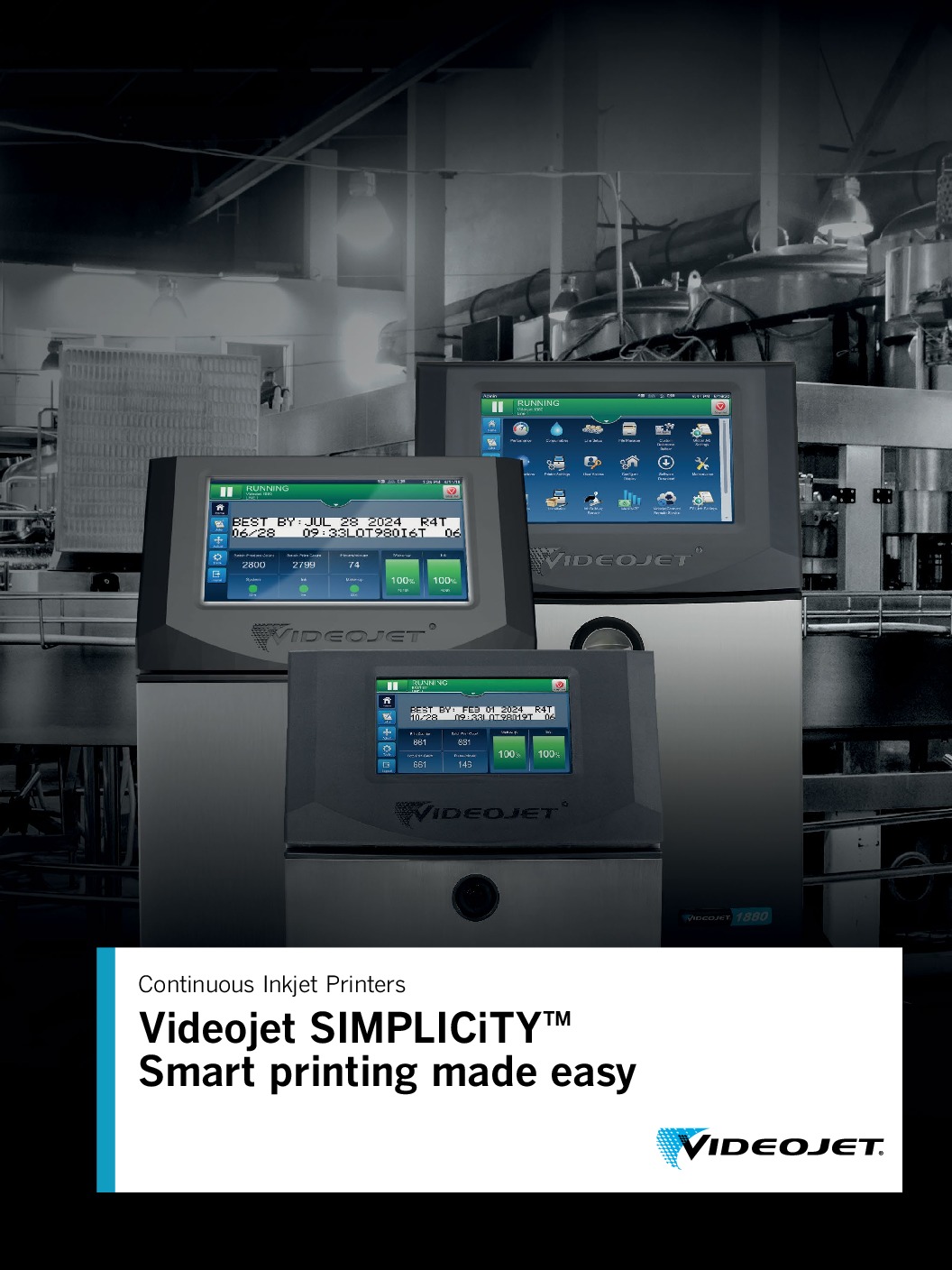

| Display (User Interface) | SIMPLICiTYTM based 10.4 inch color touchscreen |

# Optional

(1) Based upon single line, 10 characters per inch

Benefits

Harness predictive capabilities

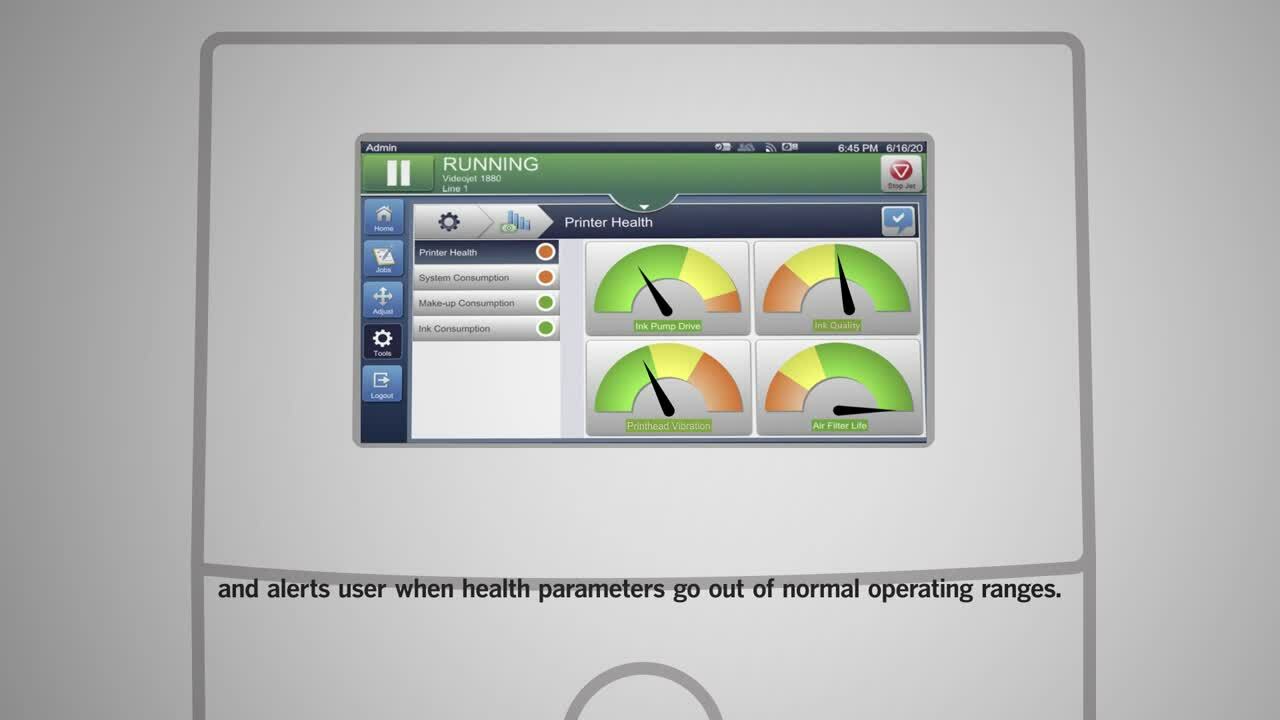

- Reduce downtime with the Videojet MAXIMiZE™ advanced diagnostics suite

- React sooner to faults and minimize the need for on-site service calls with VideojetConnect Remote Service™

- Recover from faults more quickly with RapidRecover™ automated troubleshooting engine

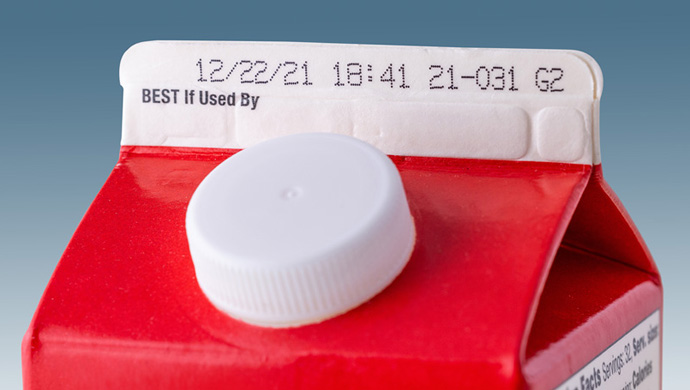

Right code at the right quality

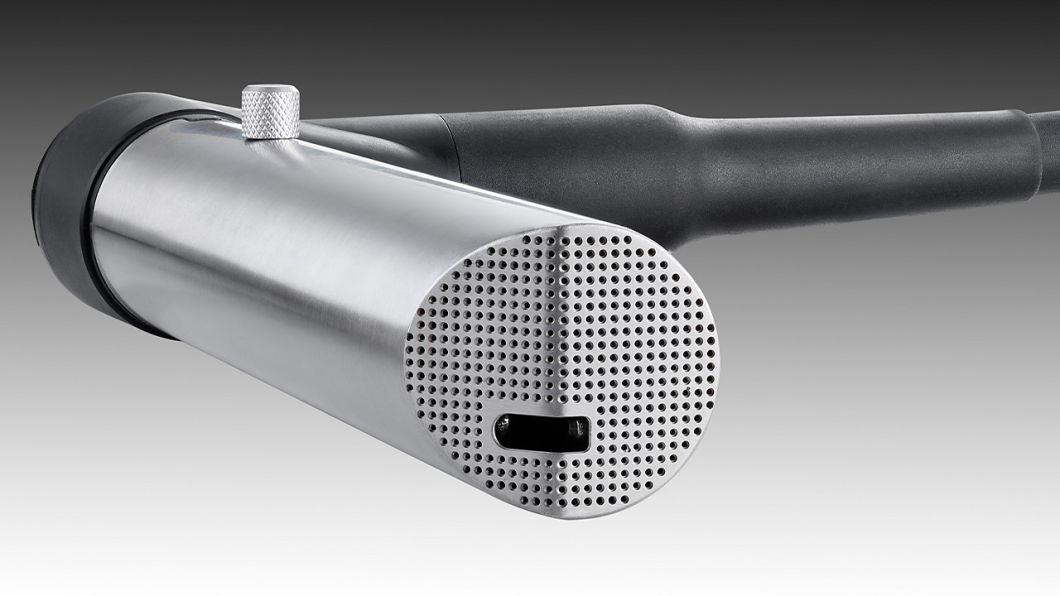

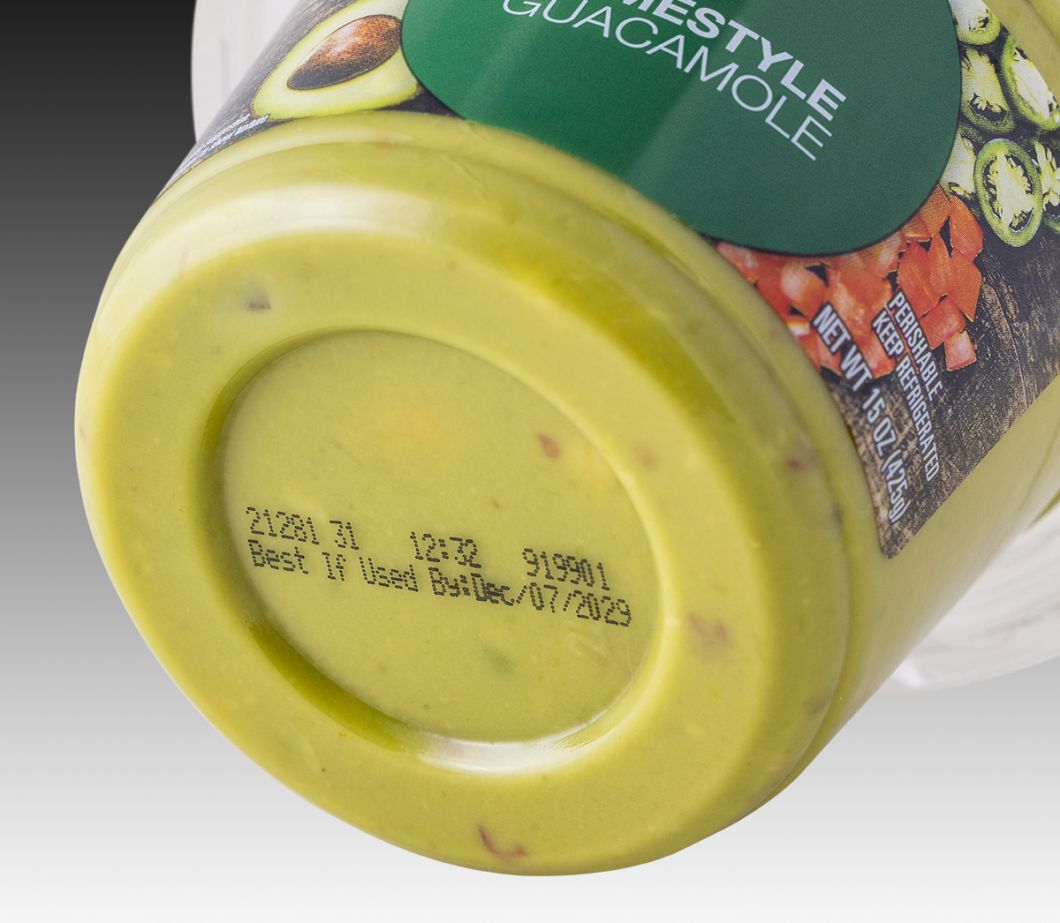

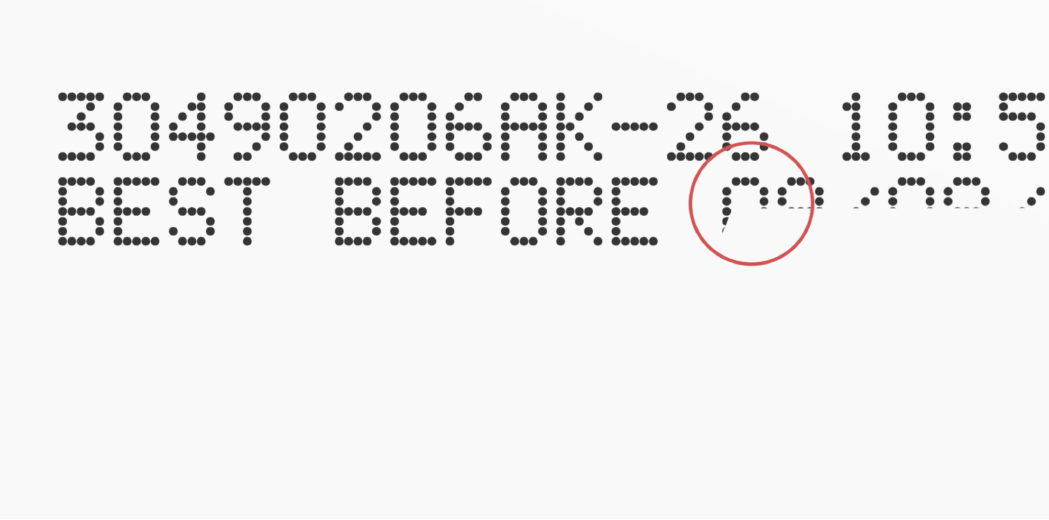

- Detect when printhead cleaning is required with the 1880 ink build-up sensor

- Simplify cleaning procedures to just a push of a button with the 1880 Auto-rinse feature

- Remove potential for human error with the suite of line integration and code management capabilities

Minimize operator interruptions

- Go longer between printhead cleanings with intelligent start-stop sequence

- Increase make-up cartridge changeover interval by up to 2x with 0.75L and 1L cartridge size options

- Easily accommodate operator-performed annual maintenance that takes just 5 minutes per year

Natural fit in your line

- Integrate into your line more easily with a dynamic rotating printhead

- Optimize for washdown with a 316 grade stainless steel, IP66 rated cabinet

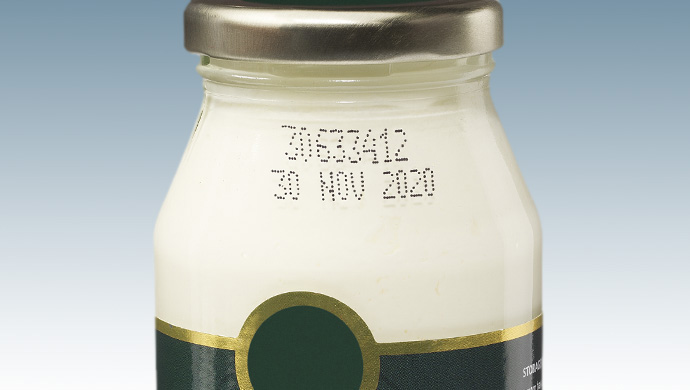

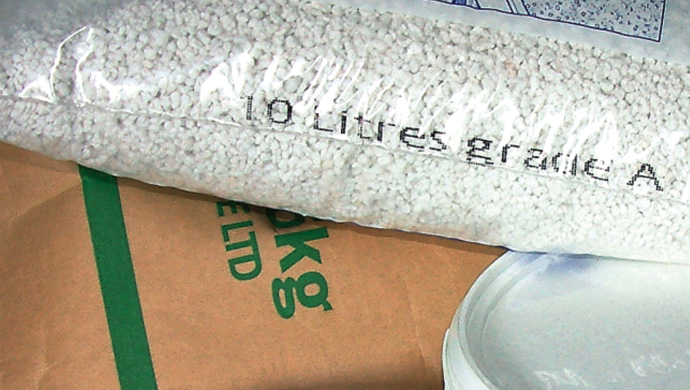

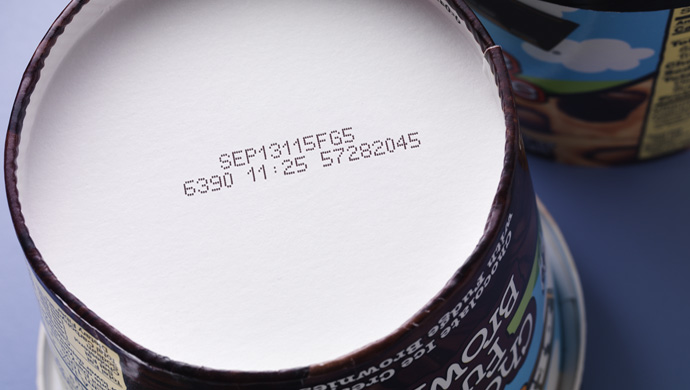

- Select from a wide variety of inks engineered to meet your application

- Withstand the toughest traversing application with a durable over-molded umbilical

“When changing cartridges there is no mess and the display indicates when replacements are needed. This enables us to monitor levels so there are no excuses for staff not to change fluids and makeup at the right time.”

Paul Ash, Maintenance Technician, Britvic (case study)

“Across our 15 bakeries, we have 200 employees who interact with the printers on a daily basis. It is very important that each of them is comfortable operating the printers. With such an intuitive interface, it is easy for them to figure out how to use the printer.”

Anton de Leeuw, National Operations Manager, Sasko Bakeries (case study)

“The Videojet project team defined the exact requirements of our application prior to arriving on site for installation so we’d be in the best possible position for the new coding solution rollout.”

Jim Gerlach, Production Scheduler, Dutch Gold Honey (case study)

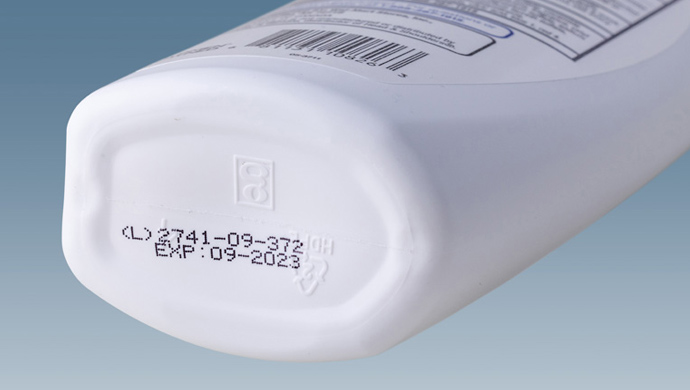

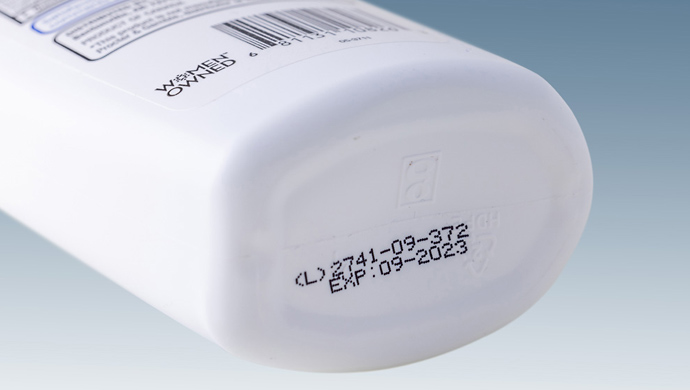

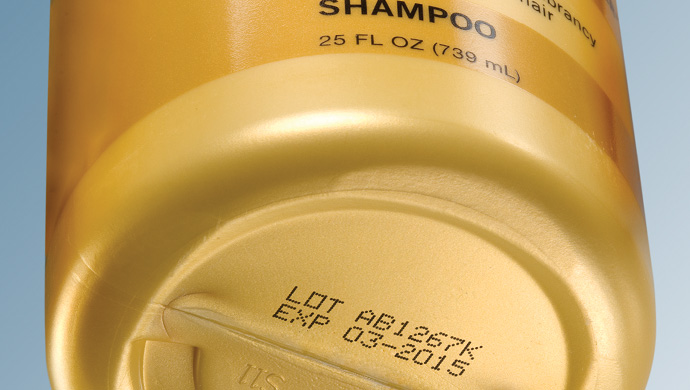

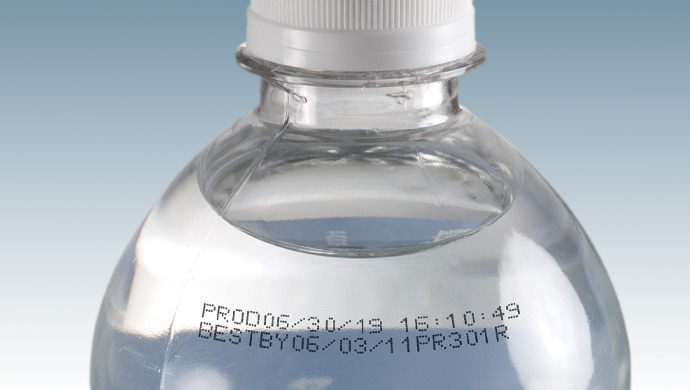

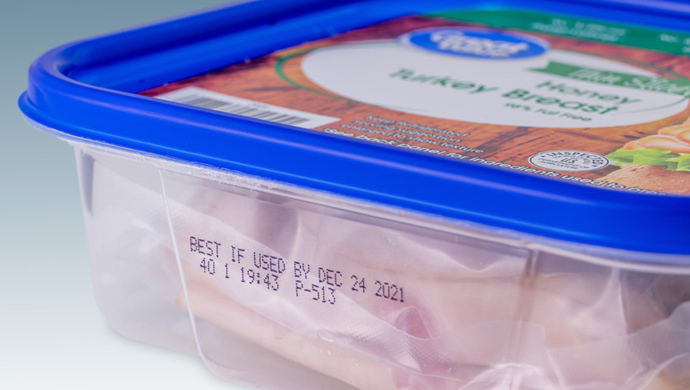

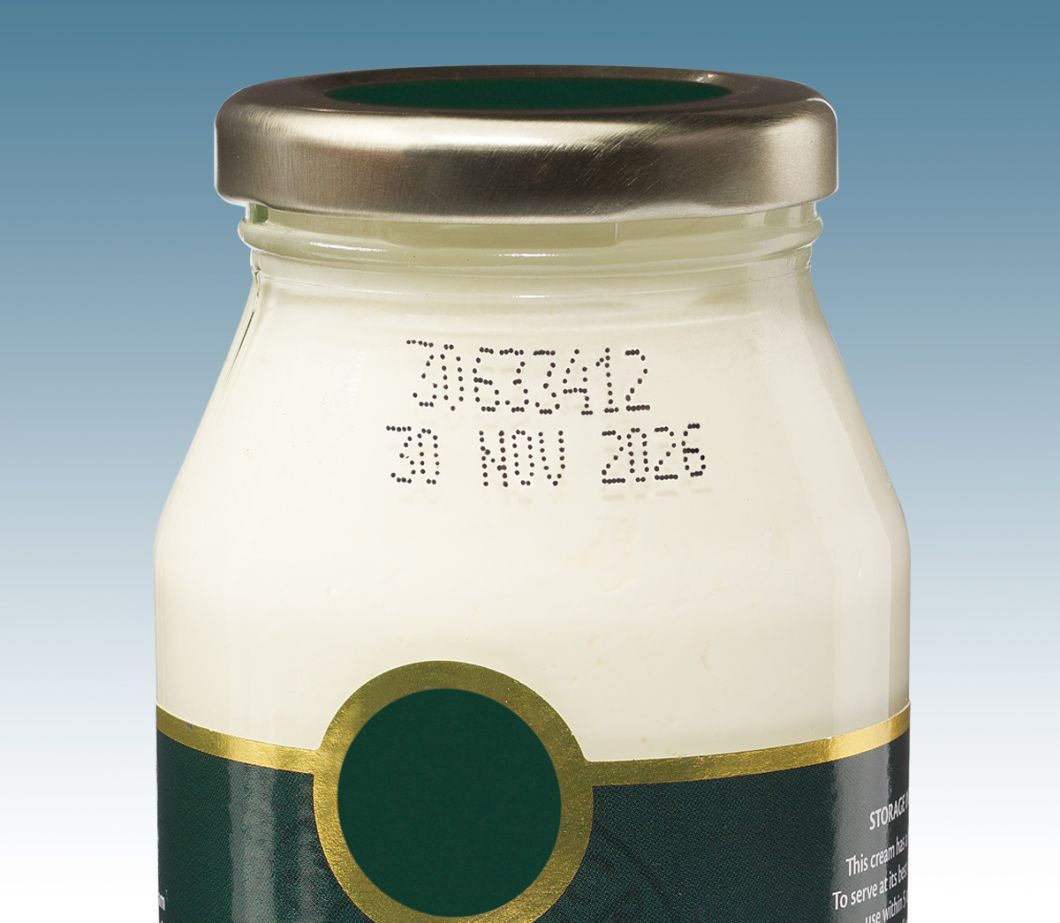

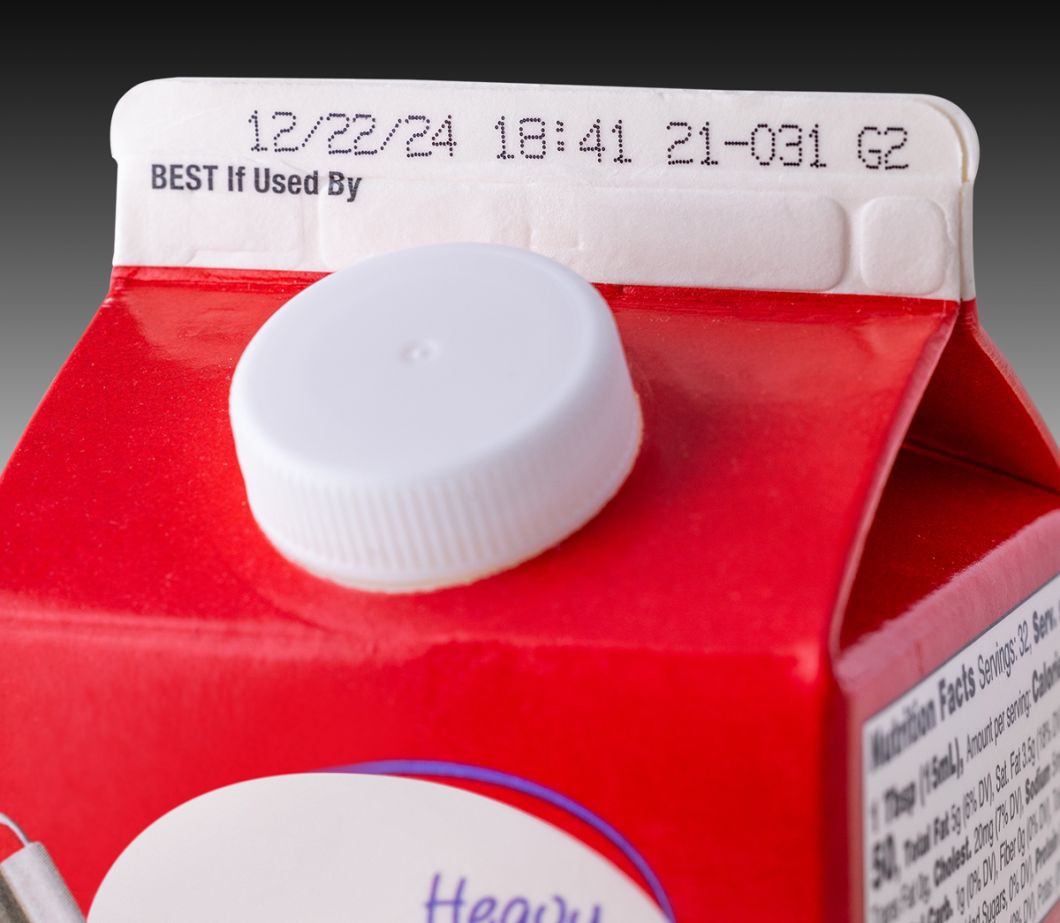

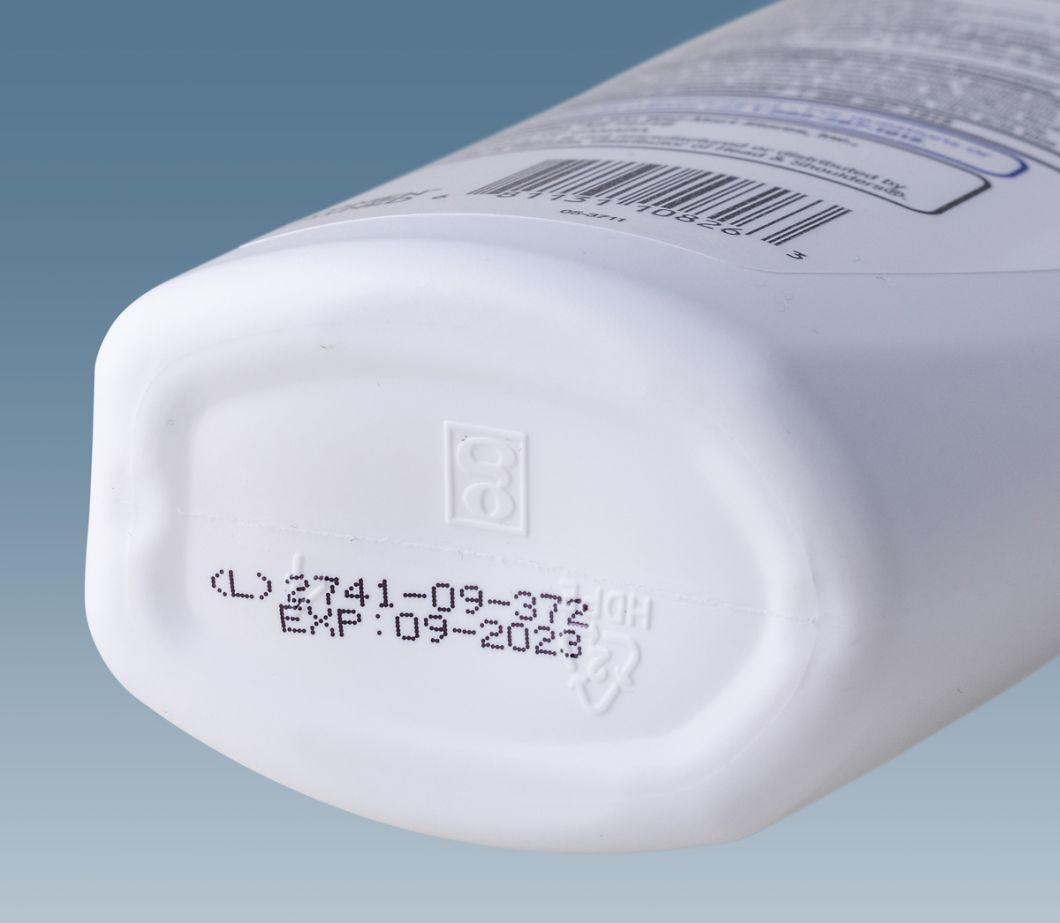

Applications

Resources

Documents

Videos

Related Products

| Videojet 1280 Continuous Inkjet  | Videojet 1580 Continuous Inkjet  | Videojet 1880 Continuous Inkjet  | |

| Max Line Speed | 162 m/min (533 ft/min) | 278 m/min (914 ft/min) | 334 m/min (1,097 ft/min) |

| Max Print Height | 10mm | 10mm | 10mm |

| Code Type | |||

| Line Location | Product Marking, Case Marking | Product Marking, Case Marking | Product Marking, Case Marking |

| Applications | Flexible Film, Foils, Labels Glass Masonry Corrugate – Direct Marking Metal Paperboard Plastic – PET Plastic – HDPE Plastic – General Rubber Textile Wood and Lumber | Flexible Film, Foils, Labels Glass Masonry Corrugate – Direct Marking Metal Paperboard Plastic – PET Plastic – HDPE Plastic – General Rubber Textile Wood and Lumber | Flexible Film, Foils, Labels Glass Masonry Corrugate – Direct Marking Metal Paperboard Plastic – PET Plastic – HDPE Plastic – General Rubber Textile Wood and Lumber |

Contact us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes:![]() 7506345599

7506345599

Service & Tech Support:![]() 1800-103-4812

1800-103-4812

E-mail:![]() marketing.india@videojet.com

marketing.india@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search