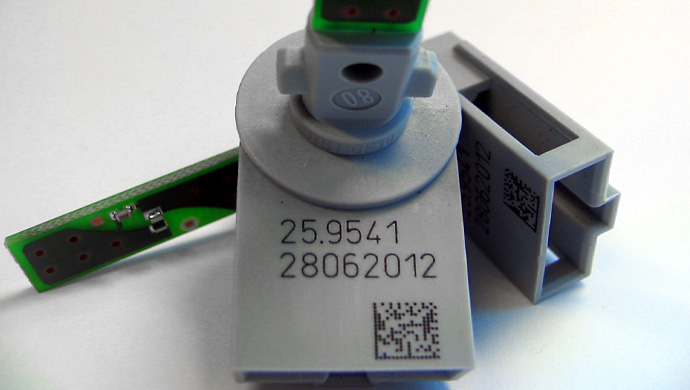

Marking and coding on plastic and rubber parts with Videojet marking and coding machines ensure traceability, compliance, and operational efficiency in various industries such as automotive, electronics, medical devices, and consumer goods. It provides information like batch numbers, manufacturing dates, serial numbers etc. Our machines are the leading solutions in offering a range of technologies to ensure durable and precise markings.

Let’s talk about why Marking and Coding are Important on rubber and plastic parts?

- It helps track parts aiding in quality control and recalls

- To meet regulations

- Authenticate products and protect against counterfeiting

Now let’s check what are the challenges in Marking on Plastic and Rubber.

- Surface Variability as it comes in various types with unique properties that can affect marking quality.

- Surface Contamination with oils and dust which can interfere with the marking process.

- Harsh environments, including exposure to chemicals, heat, and abrasion.

How Videojet Marking and Coding Solutions can play a part in achieving your desire results?

- With Continuous Inkjet Printers (CIJ) which use high-speed droplets of ink to print information on the rubber or plastics.

- With Laser Marking Systems which uses beams of light on the surface of the plastic or rubber.

- With Thermal Transfer Overprinting (TTO) which uses thermal printhead to transfer ink from a ribbon onto the surface of rubber or plastics

Suggested Solutions

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support