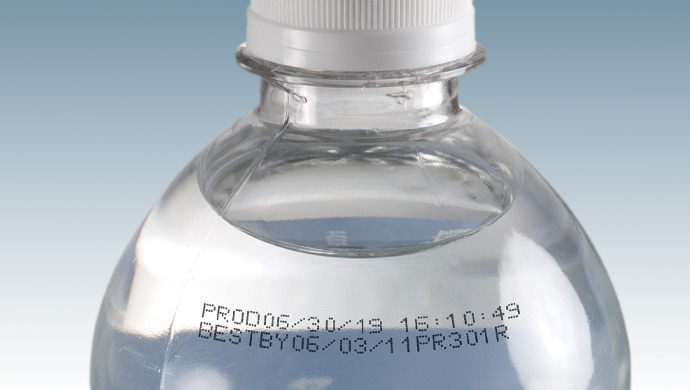

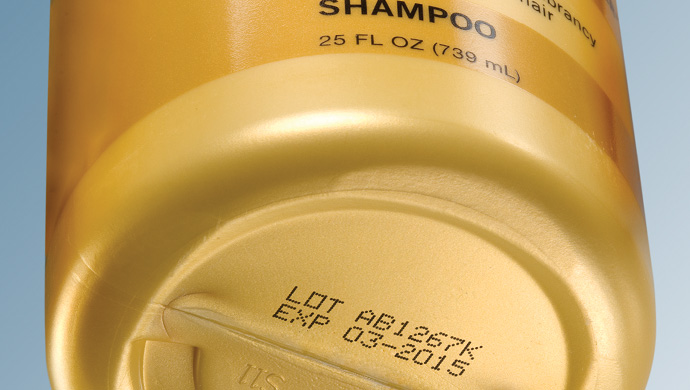

Marking and coding on PET bottle are essential processes in the beverage and packaging industry. Information that can be printed on the bottle are production dates, expiration dates, batch numbers, and other traceability data.

You can print either on the bottom of the bottle or neck of the bottle or cap of the bottle with Videojet Industrial Printers.

Why is it important to Print on PET Bottle?

- Traceability: Ensures products can be tracked through the supply chain from manufacturing to the end consumer.

- Compliance: Meets regulatory requirements for product information and safety standards.

- Quality Control: Helps in monitoring and managing production quality and identifying defective batches.

- Consumer Information: Provides consumers with important product information like expiration dates.

How can you print either on the neck, bottom or cap of the bottle?

1. Laser Marking

Non-contact method that uses laser beams to etch codes and markings directly onto the PET bottle.

What are the advantages of using laser marking machine to print on pet bottle?

- It provides high precision and clarity.

- It is permanent and tamper-proof markings.

- No consumables cost involved after buying the machine which makes it cost-effective in the long run.

What are the potential disadvantages of using laser marking and coding machine?

- initial investment cost is higher compared to other printers.

- Once the information is printed on the bottle, you can’t erase it which increase the risk of damaging the bottle.

2. Inkjet Printing

It uses non-contact inkjet technology to apply codes and markings on bottles.

Advantages of using continuous inkjet printing machine for printing on bottles:

- Flexibility to print on various surfaces and shapes which includes flat as well as curve.

- With high-speed printing capability it is suitable for mass production.

- Initial investment is low compared to Laser marking machine.

Disadvantage of choosing CIJ machine for marking and coding:

- It requires consumables like ink and solvents.

3. Thermal Transfer Overprinting (TTO)

It uses heat and pressure technology to transfer ink from a ribbon onto the PET bottle surface.

Advantages of using TTO machine for printing on bottles:

- Very high-quality and durable prints capered to CIJ.

- It is also suitable for static and variable data printing.

Along with advantages TTO also have some disadvantages which are:

- Consumable costs: Ribbons and print heads.

- It is slower technology compared to other non-contact methods.

What need to be considered before buying an industrial printing machine for marking and coding on bottles?

- External conditions like surrounding environmental: Choose an industrial printing machine which can withstand the production environment, including temperature and humidity.

- Shape and material of the bottle to ensure legible and durable markings.

- You also need to consider the production line speed to avoid bottlenecks.

Preferred Printers for Pet Bottles:

Single Head 5-lines dye-based inks with a speed of 278m/min with a capability of more than 250 complex messages with 8” touchscreen display.

CO2 laser tube with 30W of maximum power comes with fan-based cooling system and print speed of 1300 characters/sec & line speed of 360 m/min.

Additional Resources

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support