Printing on Glass Bottles and Containers

Leverage Videojet continuous inkjet or laser technology for printing on glass bottles

Glass bottles and containers remain a popular packaging option for a number of reasons, including product differentiation and identification of a premium product. Glass bottles are popular for a variety of food and beverage products, especially those that require a strong protection barrier.

From high-speed lines to high condensation environments, beverage producers operate in some of the most demanding production conditions.

Videojet offers a broad range of continuous inkjet (CIJ) and laser solutions for printing and marking on glass bottles.

Videojet continuous inkjet solutions

Continuous inkjet (CIJ)

Videojet 1880 HR

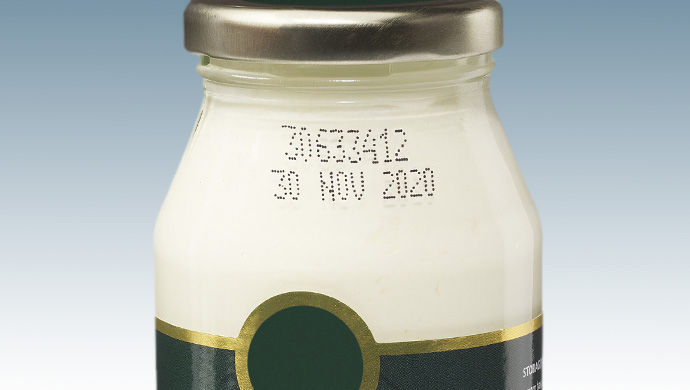

Delivers sharp, legible codes as small as 1.2mm on glass bottles and containers at speeds up to 300 m/min, perfect for limited print areas.

Continuous inkjet (CIJ)

Videojet 1580 C

Delivers high-contrast, long-lasting codes on glass bottles and containers, with easy touchscreen operation and performance insights.

Continuous inkjet (CIJ)

Videojet 1610 DH

Dual printheads efficiently print more content on glass bottles and containers at speeds up to 293 m/min for high-speed production.

Videojet laser solutions

Laser marking system

Videojet 3640

60W CO2 laser delivers high-speed serialization of up to 2,100 characters/second, helping ensure quality, traceability, and minimal codi…

Laser marking system

Videojet 3550

30W laser offers high-speed performance, printing up to 2,000 characters/second with automated features for high-quality, permanent codes on glass.

Laser marking system

Videojet 7230/7330

10 and 20W fiber lasers deliver permanent, high-quality codes on glass bottles, featuring a compact design and fast, adaptable marking for diverse …

Applications

Resources

Videos