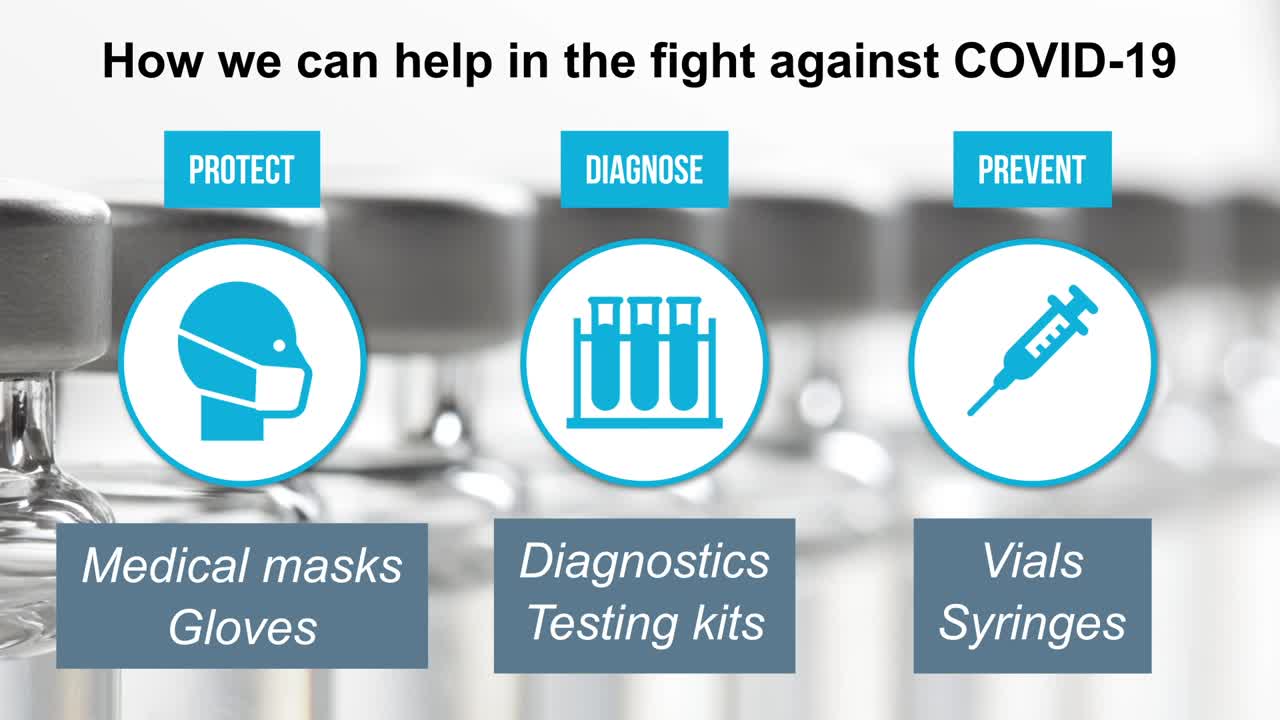

Videojet responds to the increasing demand for personal protective equipment (PPE), diagnostics, vials and syringes by shifting its technologies and resources to meet the needs of essential manufacturers during these challenging times.

Coding on medical masks

Medical masks that comply with FFP2, FFP3, N95 or KN95 standards are generally required to be labeled directly. Typical coding requirements are:

- Manufacturer’s business name, a registered trademark, or an easily understood abbreviation of manufacturer’s business name, e.g. company logo

- Testing and Certification approval number, e.g. EN 149:2001

- Filter series and filter efficiency level, e.g., N95, FFP2 or KN95

- The model number or part number, represented by a series of numbers or alphanumeric markings, e.g., 9455 or 9455A

- Lot number

- Date of production

Thermal Inkjet, UV Laser and Binary Array are common technologies to print directly onto non-woven fabrics like face masks. For more information, click here to download our application note about coding on medical masks

Coding on diagnostics

Testing kits are commonly packed in film, medical-grade paper or DuPont™ Tyvek®. Videojet offers four coding technologies that can be considered for direct printing on these substrates:

If you are interested in learning more about applying variable data directly onto or DuPont™ Tyvek®, click here to download the application note.

Coding on vials

Whether being used for customer-facing information or bright stocking, coding injectable products are inherently challenging, given the small size and reduced radius of the packaging. Integrating the coding solution into OEM equipment provides improved product control, leading to higher quality human and machine readable codes. Watch our video and learn how Videojet offers coding solutions for vials – even when space is tight.